-

- Alle Zentrifugen

- Tischzentrifugen

- Standzentrifugen

- Gekühlte Zentrifugen

- Mikrozentrifugen

- Mehrzweckzentrifugen

- Hochgeschwindigkeitszentrifugen

- Ultrazentrifugen

- Concentrator

- IVD Produkte

- High-Speed and Ultracentrifuge Consumables

- Zentrifugenröhrchen

- Zentrifugenplatten

- Gerätemanagement

- Proben- und Informationsmanagement

-

- Alle Pipetten, Dispenser und automatischen Liquid-Handling-Systeme

- Mechanische Pipetten

- Elektronische Pipetten

- Mehrkanalpipetten

- Direktverdrängerpipetten & Dispenser

- Pipettenspitzen

- Flaschenaufsatzdispenser

- Pipettierhilfen

- Zubehör für Dispenser & Pipetten

- Automatisches Pipettieren

- Verbrauchsartikel für die Automation

- Zubehör für die Automation

- Services für Dispenser & Pipetten

Regarding suitability of Eppendorf bioprocess equipment in GMP-regulated applications, please reach out to your Eppendorf sales representative.

Stem Cell Bioprocessing

Bioreactors for stem cells

Stem cell process development

Stem cell process transfer from R&D to production

Eppendorf bioreactors for stem cells

Customer success stories

Stirred-tank bioreactors facilitate the efficient expansion of stem cells through their scalable design, the ability to tightly control key parameters, and automation. Learn more about bioreactors for stem cells and how to get started with stem cell bioprocessing.

Mehr erfahren

Bioreactors for stem cells

What are bioreactors?

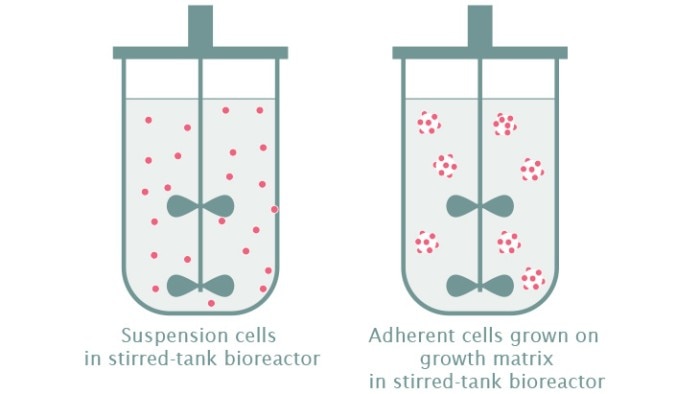

The success of stem cell bioprocessing relies on robust and reproducible culture conditions and processes. Bioreactors are vessels used to culture a broad range of cell types in precisely controlled conditions to provide optimal productivity, efficiency, and product quality. Bioreactors come in a range of sizes from milliliters to hundreds of liters. They can either be single-use or made of glass or stainless steel.

Mehr erfahren

What are the benefits of bioreactors for stem cell cultivation?

- Better reproducibility: In bioreactors you can monitor critical culture parameters including pH , Dissolved Oxygen (DO) , temperature and nutrient feeding and automatically adjust them by bioprocess monitoring and control software. Like this, culture conditions and as a result culture outcome can be better reproduced.

- Simpler scale-up: Many stem cell applications in cell therapy development, drug discovery, and lab-grown meat require high cell numbers. When using a bioreactor one can increase the size of the culture vessel to many liters and even more, unlike cell culture flasks where the number of vessels must be increased after a certain point. Using one big vessel instead of many small ones saves space and manual labor, thus simplifying the process of increasing the number of cultured cells.

Mehr erfahren

Mehr erfahren

How to use bioreactors for stem cell expansion?

The majority of stem cells are adherent cells and require a support matrix to grow. In 2D cultures, this means growing stem cells in dishes or flasks, however, these systems are often challenging to scale-up. Fortunately, there are many available options to grow adherent cells in bioreactors including:

- Cell-only aggregates: This technique involves allowing cells to adhere to one another and form an aggregate. This technique is often used for the cultivation of induced pluripotent stem cells (iPSCs) in bioreactors.

- Microcarriers: Microcarriers are spherical beads, which are added to the culture medium and serve as a surface for adherent cells such as mesenchymal stem cells (MSCs) to attach and grow. Microcarriers are made of a variety of materials. They can have specific coatings to enhance cell attachment, yield and viability.

- Fibra-Cel® Disks: Disks made of polyester and polypropylene provide a growth support for adherent cells in both packed-bed bioreactors and in suspension. Due to their three-dimensionality and fibrous material, Fibra-Cel Disks allow for easy cell attachment, a high surface-to-volume-ratio, and provide a low-shear environment. This often results in increased total biomass compared to many microcarriers.

Mehr erfahren

Mehr erfahren

How to use bioreactors for stem cell differentiation?

Mehr erfahren

How can I switch from stem cell culture in flasks and dishes to bioreactors?

Mehr erfahren

Infographic: Stem cell culture in bioreactors

Download our infographic for some tips to help you transfer your stem cell culture from dishes and flasks to bioreactors.

Interview: Increasing hiPSC yields

Robert Zweigerdt fromHannover Medical Schoolexplains how his groupconverted stem cell culture to bioreactors and which process optimization measures were crucial to increase the cell yield.

Panel discussion: Preparing your stem cell cultivation for commercialization

At what point in yourdevelopment should youconsider which cultivation method? How to switch from static to stirred-tank cultivation? Listen to experts from the Cell and Gene Therapy Catapult and Eppendorf to discover answers to these and more questions.

How to culture mesenchymal stem cells in bioreactors?

Mehr erfahren

Read our application notes for some guidelines on how to culture MSCs in bioreactors

How to culture iPSCs in bioreactors?

Mehr erfahren

Read our application notes for some guidelines on how to culture hiPSCs in bioreactors

Stem cell process development

How can I establish a robust, reproducible stem cell bioprocess?

How to monitor and control a bioprocess

Mehr erfahren

How to develop a bioprocess

Mehr erfahren

How can I increase the yield of my stem cell culture in bioreactors?

Find out, how the group of Robert Zweigerdt at MH Hannover increased hiPSC yield tenfold to 35 million hiPSCs per mL by optimizing process parameters and feeding strategy.

Mehr erfahren

How to produce stem cell-derived exosomes in bioreactors?

Mehr erfahren

Stem cell process transfer from R&D to production

What bioprocess equipment does Eppendorf offer for stem cell manufacturing?

Mehr erfahren

Where can I find more information about the role of stirred-tank bioreactors in stem cell manufacturing?

- Watch webinar : Join experts from Hannover Medical School, Pluri Inc., and Eppendorf and find out more about unleashing the power of stirred-tank bioreactors for cell and gene therapies!

- Access the recording of scientifc talks from our last Stem Cell Community Day to get expert insights into stem cell process development, scale-up, and manufacturing.

Mehr erfahren

Stem cell expertise at Eppendorf

With hands-on experience in stem cell culture using bioreactors, our lab applications team has authored comprehensive application notes on stem cell bioprocessing, allowing our customers to leverage this expertise through readily accessible, practical guidance. Have a look at some of them here:

Mehr erfahren

Application notes on stem cell bioprocessing from the Eppendorf applications labs

Join the stem cell community!

Mehr erfahren